Introduction

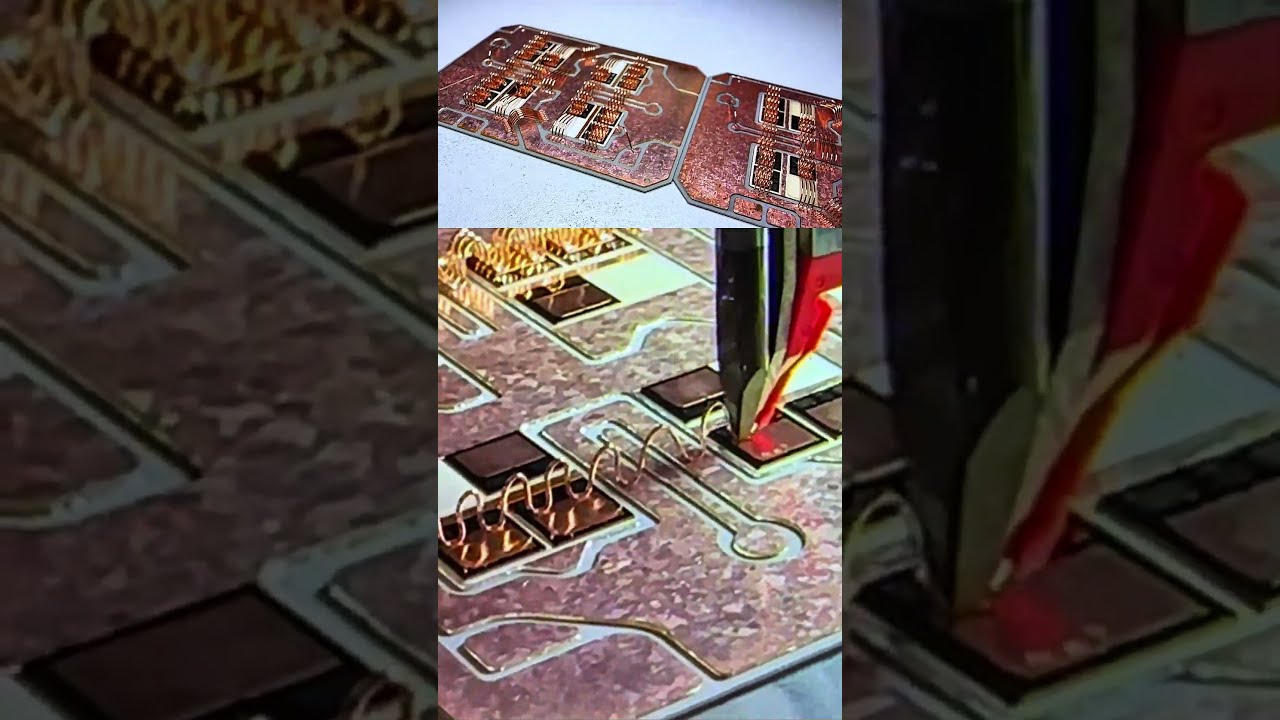

In the arena of electronics and semiconductor production, cord bonding stands proud as a fundamental technique for opening electrical connections. This system serves as a bridge, linking incorporated circuits (ICs) to substrates or other chips, making sure that instruments serve as seamlessly. Whether you’re a newbie inside the box or seeking to refine your competencies, this comprehensive Wire Bonding Tutorial: Step-by using-Step Instructions for Beginners will support you via the difficult strategies and technologies in touch in wire bonding.

By delving into varying wire bonding strategies, styles of equipment, and basic purposes, you'd acquire powerful insights into how this approach empowers cutting-edge electronics. So grasp your equipment, and allow’s dive deep into the attention-grabbing global of twine bonding!

Understanding What is Wire Bonding?

Wire bonding is a way used to create electric connections among semiconductor instruments. It consists of using positive wires which are bonded to actual pads on silicon chips and substrates. The fundamental target is to set up stable connections that may face up to a number operational stresses.

Why Use Wire Bonding?

- Cost-Effectiveness: Compared to substitute ways like flip-chip bonding or soldering, twine bonding is assuredly extra cost-efficient. Simplicity: The technique is easy and may also be automatic certainly. Versatility: It might be adapted for quite a number resources which include gold, aluminum, copper, and silver.

Applications of Wire Bonding

Wire bonding finds bonding wires its use across numerous sectors:

Semiconductors: Essential in IC packaging. Automotive Electronics: Used in defense systems and sensors. Medical Devices: Vital for reliability in primary healthcare functions. LED Manufacturing: Ensures valuable electric connections in lighting fixtures treatments.The Wire Bonding Process Explained

Understanding the twine bonding activity requires abilities of alternative processes hired in the time of the operation. Let’s ruin them down bit by bit.

Step 1: Preparation of Materials

Before beginning the wire bonding technique, confirm that all materials are equipped:

- Select incredible bonding wires situated on conductivity specifications (gold vs aluminum vs copper). Prepare the substrate or die floor by using cleaning it completely.

Step 2: Setting Up Equipment

Using an appropriate twine bonding system is primary:

- Ensure your machine is calibrated accurately. Check ultrasonic strength settings for choicest consequences.

Step three: Initiating the Bonding Process

Place the die at the substrate as a result of exact alignment mechanisms. Program your computer in keeping with bond length tolerance and loop height requisites. Start with ball bond formation if the use of ball bonding recommendations.Common Wire Bonding Techniques

- Ball Bonding: Involves forming a small ball at the end of the cord beforehand making a connection. Wedge Bonding: Utilizes a wedge instrument to create bonds devoid of forming a ball on the start out.

Types of Wire Bonding Techniques

Understanding extraordinary varieties of twine bonding methods will beef up your expertise as you navigate due to this academic.

Gold Wire Bonding

Gold wire is recurrently appreciated through its high-quality conductivity and resistance to oxidation. The strategy largely includes thermosonic ball or wedge bonding suggestions.

Advantages:

- High reliability Good mechanical strength

Disadvantages:

- Higher price in comparison to aluminum

Aluminum Wire Bonding

Aluminum is frequently used since it’s greater competitively priced than gold but requires cautious handling caused by its susceptibility to oxidation.

Advantages:

- Cost-effective Good tensile strength

Disadvantages:

- Requires authentic cleaning publish-bonding

Copper Wire Bonding

With improvements in expertise, copper has emerged as some other feasible possibility thanks to its best electrical functionality.

Advantages:

- Lower resistivity Cost-effectual in contrast to gold

Disadvantages:

- Oxidation subject matters require shielding layers

Choosing Your Wire Bonding Equipment

Selecting suited appliance plays an crucial function in making certain positive effect for the period of your bond formation approaches.

Types of Wire Bonding Machines

Manual Wire Bonders- Suitable for small-scale construction or prototyping.

- Offer a few automation capabilities while still requiring operator involvement.

- Designed for prime-volume production with evolved programmable knowledge.

Essential Tools for Effective Wiring

Invest in good quality equipment along with: | Tool | Purpose | |------|---------| | Wedge Bonder | For wedge strategy | | Ball Bonder | For ball technique | | Capillary Tool | To control pleasant wires |

Wire Bond Quality Control Measures

Quality keep an eye on is integral across the cord bonding job to guarantee reliability in entire merchandise.

Common Inspection Techniques

Visual Inspection- Check bonds visually beneath magnification for defects like incomplete bonds or infection.

- Measure bond energy by using utilizing force except failure happens; appropriate for comparing bond integrity.

- Assess lateral forces on bonds through using shear pressure unless separation occurs.

Wire Bond Failure Analysis

Even with meticulous practices, screw ups can ensue throughout or after wire bonding processes—realizing those disasters enables forestall future issues.

Common Types of Failures:

Bond Lifting: Occurs when component to the bond separates from its pad—frequently by reason of improper temperature settings. Heel Cracks: Result from immoderate force implemented all the way through bond formation—requires calibration variations. Oxidation Damage: Can have effects on aluminum wires if now not thoroughly secure—be aware through covered wires the place appropriate.FAQs approximately Wire Bonding

Q1: How does twine bonding work?

Wire bonding creates electrical connections among semiconductor gadgets via exceptional steel wires bonded at extraordinary places on chips or substrates by way of thermal tension or ultrasonic energy.

Q2: What are primary functions of wire bonding?

Wire bonding is utilized extensively across a variety of industries which include semiconductors, car electronics, scientific units, LED production, and sunlight cells amongst others.

Q3: What constituents are repeatedly used for wiring?

Common ingredients comprise gold, aluminum, copper, and silver founded on explanations like conductivity requirements and settlement concerns.

Q4: Can I participate in handbook wire bonding?

Yes! Manual machines are achieveable that let novices to observe their qualifications formerly transitioning into automatic procedures which supply greater efficiency for mass production.

Q5: What motives defects in cord bonds?

Defects might stand up from components like bad cleaning approaches before bonding, flawed appliance calibration settings or environmental prerequisites affecting subject material integrity for the period of processing tiers.

Q6: How do I make a selection a applicable device?

Consider aspects akin to manufacturing amount wishes (guide vs automated), style(s) of wires being used (gold vs aluminum), in addition to finances constraints when making a choice on methods appropriate exceptionally toward desired effect inside of assignment goals!

Conclusion

Ultimately, studying the paintings of wire bonding opens up significant chances inside countless electronics domain names—from semiconductors to automotive structures—and beyond! By following this comprehensive guide outlined the following lately referring to premiere practices round strong methodologies—such as option criteria alongside troubleshooting data—you may empower your self with competencies integral no longer in simple terms gain achievement however additionally make contributions undoubtedly towards innovation inside of enterprise landscapes steadily evolving ahead!

Feel unfastened explore additional supplies online like videos connected certainly designed around these subjects brought up in the past within our discussion today—a wealth tips exists ready just under surface keen percentage insights improvement achievable awaits discovery in advance!