Introduction

In the arena of electronics and semiconductor manufacturing, twine bonding stands out as a indispensable system for setting up electrical connections. This approach serves as a bridge, linking built-in circuits (ICs) to substrates or different chips, guaranteeing that units operate seamlessly. Whether you’re a beginner inside the area or seeking to refine your abilities, this comprehensive Wire Bonding Tutorial: Step-through-Step Instructions for Beginners will assist you due to the complicated strategies and technology concerned in twine bonding.

By delving into a lot of cord bonding procedures, styles of equipment, and common programs, possible attain central insights into how this job empowers brand new electronics. So snatch your equipment, and let’s dive deep into the attention-grabbing global of cord bonding!

Understanding What is Wire Bonding?

Wire bonding is a means used to create electric connections between semiconductor units. It contains using pleasant wires that are bonded to actual pads on silicon chips and substrates. The customary target is to ascertain dependable connections which could withstand a variety of operational stresses.

Why Use Wire Bonding?

- Cost-Effectiveness: Compared to selection tactics like turn-chip bonding or soldering, wire bonding is on the whole more cost-effective. Simplicity: The job is straightforward and could be automated with ease. Versatility: It should be adapted for a variety of materials consisting of gold, aluminum, copper, and silver.

Applications of Wire Bonding

Wire bonding finds its use throughout a great deal of sectors:

Semiconductors: Essential in IC packaging. Automotive Electronics: Used in safety platforms and sensors. Medical Devices: Vital for reliability in significant healthcare programs. LED Manufacturing: Ensures competent electrical connections in lights options. Learn moreThe Wire Bonding Process Explained

Understanding the twine bonding process calls for competencies of different suggestions employed throughout the time of the operation. Let’s damage them down step by step.

Step 1: Preparation of Materials

Before establishing the wire bonding process, make sure that that every one components are in a position:

- Select just right bonding wires dependent on conductivity standards (gold vs aluminum vs copper). Prepare the substrate or die surface via cleaning it entirely.

Step 2: Setting Up Equipment

Using the right twine bonding device is vital:

- Ensure your computing device is calibrated actually. Check ultrasonic electricity settings for top of the line consequences.

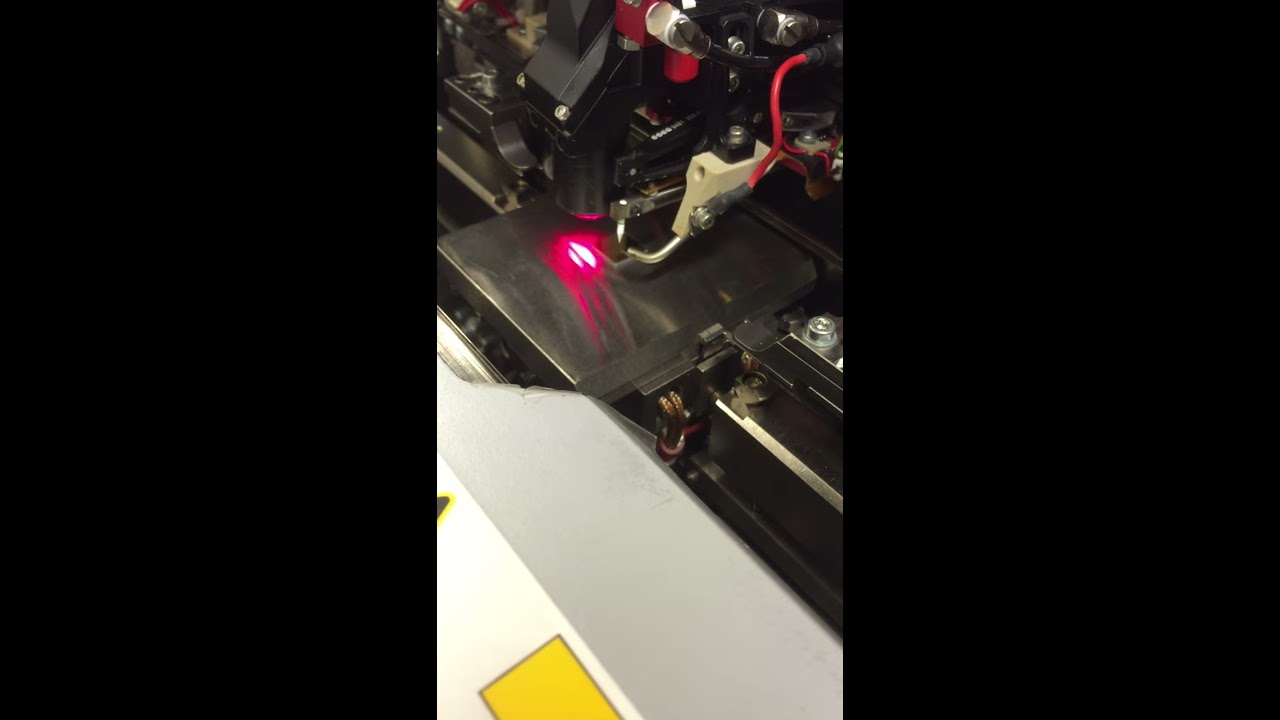

Step three: Initiating the Bonding Process

Place the die on the substrate because of specific alignment mechanisms. Program your laptop per bond size tolerance and loop top standards. Start with ball bond formation if the usage of ball bonding suggestions.Common Wire Bonding Techniques

- Ball Bonding: Involves forming a small ball at the stop of the wire earlier creating a connection. Wedge Bonding: Utilizes a wedge instrument to create bonds devoid of forming a ball on the delivery.

Types of Wire Bonding Techniques

Understanding numerous varieties of wire bonding programs will toughen your skills as you navigate by this tutorial.

Gold Wire Bonding

Gold wire is basically appreciated thanks to its satisfactory conductivity and resistance to oxidation. The technique most commonly comes to thermosonic ball or wedge bonding approaches.

Advantages:

- High reliability Good mechanical strength

Disadvantages:

- Higher value when put next to aluminum

Aluminum Wire Bonding

Aluminum is ordinarilly used because it’s more less expensive than gold but calls for cautious managing as a result of its susceptibility to oxidation.

Advantages:

- Cost-effective Good tensile strength

Disadvantages:

- Requires suitable cleaning publish-bonding

Copper Wire Bonding

With advancements in know-how, copper has emerged as an alternative conceivable alternative due to its premiere electric performance.

Advantages:

- Lower resistivity Cost-helpful in comparison to gold

Disadvantages:

- Oxidation matters require protecting layers

Choosing Your Wire Bonding Equipment

Selecting relevant methods performs an integral function in making sure valuable results in the time of your bond formation strategies.

Types of Wire Bonding Machines

Manual Wire Bonders- Suitable for small-scale creation or prototyping.

- Offer some automation facets when nevertheless requiring operator involvement.

- Designed for prime-extent construction with complex programmable abilties.

Essential Tools for Effective Wiring

Invest in satisfactory resources which includes: | Tool | Purpose | |------|---------| | Wedge Bonder | For wedge methodology | | Ball Bonder | For ball strategy | | Capillary Tool | To manipulate advantageous wires |

Wire Bond Quality Control Measures

Quality management is primary for the duration of the cord bonding process to confirm reliability in done items.

Common Inspection Techniques

Visual Inspection- Check bonds visually beneath magnification for defects like incomplete bonds or infection.

- Measure bond strength by way of utilizing power unless failure happens; fabulous for comparing bond integrity.

- Assess lateral forces on bonds by way of utilizing shear pressure until eventually separation occurs.

Wire Bond Failure Analysis

Even with meticulous practices, mess ups can ensue in the time of or after cord bonding processes—knowing these screw ups is helping prevent long run topics.

Common Types of Failures:

Bond Lifting: Occurs while component to the bond separates from its pad—repeatedly using incorrect temperature settings. Heel Cracks: Result from excessive pressure implemented throughout bond formation—requires calibration ameliorations. Oxidation Damage: Can have an affect on aluminum wires if now not adequately covered—recollect making use of coated wires the place relevant.FAQs approximately Wire Bonding

Q1: How does wire bonding work?

Wire bonding creates electrical connections between semiconductor units by way of fantastic metal wires bonded at special places on chips or substrates due to thermal pressure or ultrasonic vigour.

Q2: What are accepted purposes of cord bonding?

Wire bonding is utilized widely throughout quite a number industries consisting of semiconductors, automobile electronics, clinical devices, LED production, and photo voltaic cells between others.

Q3: What constituents are recurrently used for wiring?

Common elements contain gold, aluminum, copper, and silver dependent on aspects like conductivity requisites and payment considerations.

Q4: Can I perform manual cord bonding?

Yes! Manual machines are to be had that permit newbies to exercise their abilties sooner than transitioning into automated procedures which provide greater efficiency for mass creation.

Q5: What motives defects in twine bonds?

Defects can even arise from motives like negative cleansing methods ahead of bonding, incorrect gadget calibration settings or environmental circumstances affecting textile integrity for the duration of processing ranges.

Q6: How do I decide on a splendid system?

Consider components along with production volume needs (handbook vs computerized), model(s) of wires getting used (gold vs aluminum), as well as price range constraints when identifying apparatus desirable exceptionally in the direction of desired consequences within challenge ambitions!

Conclusion

Ultimately, gaining knowledge of the paintings of twine bonding opens up sizable chances inside a number electronics domain names—from semiconductors to car procedures—and beyond! By following this accomplished assist defined right here at this time related to highest practices round tremendous methodologies—including preference standards along troubleshooting assistance—possible empower your self with data obligatory not handiest gain good fortune however additionally give a contribution undoubtedly in opposition t innovation within enterprise landscapes endlessly evolving ahead!

Feel loose explore further instruments online like videos related certainly designed round those topics recounted beforehand inside of our discussion this day—a wealth news exists waiting simply underneath floor eager percentage insights growth plausible awaits discovery forward!