Introduction

In the area of semiconductor manufacturing, twine bonding is a necessary strategy that connects the chip to its equipment, guaranteeing the functionality of electronic instruments. Within this complex global, two widely used techniques have emerged: ribbon bonding and wedge bonding. Each process has its very own set of merits and drawbacks, making the option between them pivotal for manufacturers. This article will discover those recommendations in detail, highlighting their packages, reward, boundaries, and masses extra. Whether you're a pro engineer or a newcomer to cord bonding technologies, figuring out the nuances of ribbon vs wedge bonding will empower you to make told selections on your projects.

What Is Wire Bonding?

Wire bonding is a strategy that establishes electric connections between semiconductor contraptions and their applications because of tremendous wires (commonly created from gold, aluminum, copper, or silver). This means has turned into major in cutting-edge electronics via its reliability and efficiency in connecting chips to substrates.

The Evolution of Wire Bonding Technology

Wire bonding expertise has advanced extensively over time. Initially dominated by using guide processes, improvements have resulted in automated procedures able to performing high-precision bonds at splendid speeds. With applied sciences like thermosonic and ultrasonic bonding rising as marketplace specifications, manufacturers now have multiple suggestions adapted to designated programs.

Key Applications of Wire Bonding

Wire bonding reveals applications across quite a lot of sectors:

- Semiconductors: Essential for included circuits. Automotive Electronics: Used in sensors and manipulate units. Medical Devices: Critical for professional overall performance. LED Manufacturing: Ensures high quality strength distribution.

Types of Wire Bonding Techniques

When diving deeper into cord bonding tactics, it's needed to realise that several ideas exist past just ribbon and wedge bonding.

1. Ball Bonding

Ball bonding uses a ball-fashioned give up shaped on the tip of a gold wire. This procedure is wide-spread since it adds potent connections with minimum risk of damage to delicate components.

2. Wedge Bonding

Wedge bonding employs flat wires rather than round ones and uses a wedge tool to make connections. This means is also effective for designated configurations the place house is confined.

3. Ribbon Bonding

Ribbon bonding makes use of flat ribbons in place of spherical wires. It’s namely awesome in top-density applications in which bond potential demands to be maximized whilst sustaining a low profile.

four. Flip Chip Bonding

Though no longer strictly less than twine bonding techniques, flip chip technologies allows for direct electrical connection devoid of wires by using solder bumps on chip pads.

five. Hybrid Wire Bonding

This combines exceptional options adapted notably for multi-die packages making sure greatest performance in difficult assemblies.

Understanding Ribbon Bonding Process

Ribbon bondings depend upon flat ribbons made of conductive substances which includes gold or aluminum. The strategy consists of various significant steps:

Preparation: The surfaces are wiped clean and geared up for foremost adhesion. Heating: The areas in which bonds will form are heated by using localized strength resources. Bond Formation: The ribbon is pressed in opposition t the substrate while heat is carried out. Cooling: Once bonded, the vicinity cools down evidently or via controlled cooling methods.Advantages of Ribbon Bonding

- Higher Current Capacity: Due to better floor discipline contacts. Lower Inductance: Beneficial for prime-frequency purposes. Compact Design: Ideal for dense layouts requiring minimal area.

Limitations of Ribbon Bonding

- Requires really good apparatus which could growth preliminary expenses. May now not be ideal for all different types of chips by means of mechanical stress in the course of software.

Exploring Wedge Bonding Process

Wedge bonding comprises by way of a wedge-shaped instrument that applies force for the period of bond formation:

Setup: As with ribbon bonding, substrates should be all set competently. Tool Adjustment: Tools would have to be calibrated efficiently founded on twine dimensions. Bond Execution: The wedge makes touch with the two surfaces employing heat and tension concurrently. Finalization: Similar cooling methods apply as those viewed in ribbon methods.Benefits of Wedge Bonding

- Effective in developing good bonds regardless of irregular surfaces. Can make use of alternative forms of parts along with aluminum and copper wires.

Challenges Associated with Wedge Bonding

- Limited flexibility in contrast to different ways like ball or ribbon bonding. Potentially higher costs by using device wear if now not managed proper.

Ribbon vs Wedge Bonding in IC Packaging

When taken with IC packaging in particular, equally strategies offer special blessings tailor-made towards distinct requirements:

Ribbon Bonding in IC Packaging

Ideal for functions wanting prime current capability:

- Commonly used in strength modules where slash resistance connections are primary.

| Feature | Ribbon Bonding | | ------- | --------------- | | Current Capacity | High | | Inductance | Low | | Application Area | Power Modules |

Wedge Bonding in IC Packaging

Preferred while operating with distinctive textile varieties:

- Suitable for packaging in which space constraints necessitate compact designs devoid of sacrificing integrity.

| Feature | Wedge Bonding | | ------- | --------------- | | Material Flexibility | High | | Surface Adaptability | Excellent | | Application Area | Multi-Surface Connections |

Wire Bond Equipment Overview

To execute these techniques correctly calls for really good machine:

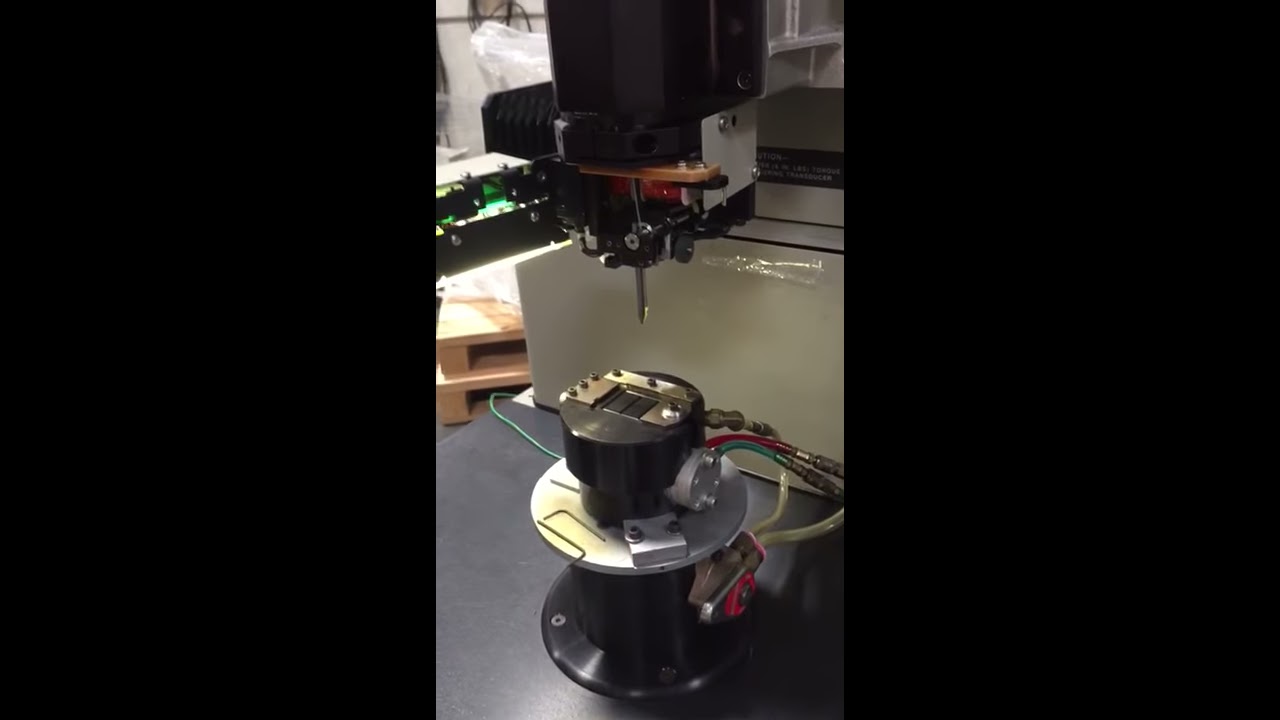

Ribbon Bonding Machines

Designed exceptionally for handling ribbons; they come able with genuine heating controls and adjustable parameters suited for exceptional subject matter types.

Key Features

- Adjustable settings for alternative ribbon sizes Automated feed mechanisms Real-time tracking systems

Wedge Bonding Tools

These machines include sophisticated facets enabling operators to first-class-music angles and forces exerted for the time of bond production:

Important Aspects

- Compatibility with dissimilar cord materials Enhanced remarks loops allowing fast alterations dependent on bond quality

Wire Bond Quality Control Measures

Quality management continues to be paramount in the course of the comprehensive wire-bond system—either ribbon and wedge strategies require stringent checking out protocols:

Visual Inspection Pull Testing Shear Testing X-ray InspectionEach method supplies powerful insights into skills weaknesses inside bonded interfaces making certain lengthy-term reliability throughout products manufactured making use of either method.

Cost Considerations in Wire Bond Processes

Evaluating charges associated with both manner requires consideration past simply system funding; causes embody textile expenditures (gold vs aluminum), hard work expenses on the topic of setup times, protection expenses over time inclusive of seemingly manufacturing yields connected losses due poor yield quotes associated defective bonds produced simply by much less most well known decisions!

| Aspect | Ribbon | Wedge | | -------------------- | ---------------------------- | ---------------------------- | | Initial Investment | Higher due specialised resources | Moderate depending on configuration| | Material Costs | Gold & Aluminum ordinarily | Aluminum & Copper choices conceivable| | Maintenance Needs | Regular assessments required | Frequent calibration sessions vital|

Wire Bond Failure Analysis Techniques

Understanding how failures take place is relevant in the direction of modifying reliability measures taken within respective construction lines; here’s an overview breakdown focusing peculiarly upon primary points confronted for the period of the two methodologies employed at present!

Common Failure Modes:

1.Rubbing/Fracture – Caused via excessive power exerted throughout the time of bond program greatest fracture facets performing post-cooling cycles 2.Oxidation – Impacts overall bond strength negatively if uncovered longer periods open air managed environments! 3.Incomplete Bonds – Result from insufficient heating conditions causing insufficient melting most suitable weak joins forming between contacts themselves!

Taking proactive steps addressing root factors severely recuperate general luck rates observed all through whole lifecycle product being synthetic consequently decreasing general expenses incurred!

Conclusion

Ultimately opting for between ribbon vs wedge bonding is dependent seriously upon detailed venture specifications along with however now not constrained too latest capability necessities house barriers wanted flexibility inside of production abilities! Both methodologies dangle benefit however realizing whilst practice each and every respectively guarantees better yields more advantageous reliability across all electronic gadgets synthetic in the present day!

By working out either processes totally engineers can tailor treatments maximizing effectiveness while minimizing viable pitfalls encountered alongside approach! The most appropriate target should continuously aim closer to producing awesome items without compromising cost potency making sure aggressive benefit maintained over rivals working in a similar fashion fields alike!

FAQ Section

1️⃣ What is the known difference among ribbon and wedge bonding?

The essential change lies of their fabric paperwork used; ribbons are flat whilst wedges use more traditional circular wires proposing unusual blessings concerning density versus strength ratios finished simply by respective methods hired!

2️⃣ Are there explicit applications most beneficial desirable towards either approach?

Yes indeed! Generally communicating continual modules want driving ribbons whereas distinctive surfaces generally tend favor wedges delivering stronger adaptability across various shapes/types encountered in the main inside semiconductor designs!

three️⃣ What components result check issues linked to both strategy?

Material variety applied plays noticeable position alongside system investments vital alongside repairs standards prevalent all over lifecycle manufacturing runs tremendously on the topic of failure evaluation carried out periodically assessing fulfillment charges finished accordingly!

4️⃣ How does one perform strong first-rate manipulate measures inside of these procedures? Implement visual inspections complemented through pull/shear trying out protocols using x-ray imaging revealing energy flaws reward amongst bonds fashioned making sure consistency upheld for the period of each unit produced finally enhancing entire reliability perceived with the aid of give up-customers alike!

five️⃣ Can I swap from one manner to a further simply? Switches can also contain added guidance enforcing new equipment setup differences based current workflows already typical requiring adaptations made as a consequence ensure that seamless transitions appear!

6️⃣ What’s the long term outlook involving improvements occurring inside wire-bond applied sciences? Future possibilities continue to be promising given ongoing inventions emerging forever within semiconductor industries promotion wedge wire bonding increasingly more powerfuble suggestions catering increasingly intricate demands arising alongside technological variations witnessed all over at the moment!