Introduction

In the instantly evolving panorama of electronics production, the value of stable interconnections is not going to be overstated. One such manner that has won traction in contemporary years is insulated twine bonding. This article delves into the tricky world of cord bonding, exploring its tactics, technology, innovations, and functions although emphasizing how insulated twine bonding enhances efficiency and toughness.

What is Insulated Wire Bonding?

Insulated twine bonding comes to using insulation parts on bonding wires to improve electrical performance even as minimizing disadvantages akin to short circuits and cross-talk. This approach is awfully worthy in high-density packaging programs the place area is at a top rate. By delivering an additional layer of security, insulated wire bonding guarantees that digital gadgets are not solely successful however additionally long-lasting.

Understanding the Wire Bonding Process

The wire bonding process incorporates various primary steps:

Preparation: The substrate is prepared by way of cleansing and applying a conductive layer. Wire Selection: The ideal variety of wire (gold, aluminum, copper) is chosen based mostly on utility standards. Bonding: A bond is created between the wire and the substrate using heat, tension, or ultrasonic vigor. Testing: The bonds are examined for reliability by using varying tips like pull tests or shear checks.Types of Insulation Materials Used

The selection of insulation drapery performs a pivotal role in finding out the effectiveness of insulated cord bonding. Common resources incorporate polyimide movies, silicone rubbers, and epoxy resins. Each material promises distinct houses similar to thermal steadiness and chemical resistance.

The Importance of Wire Bonding Technology

Advancements in Wire Bonding Equipment

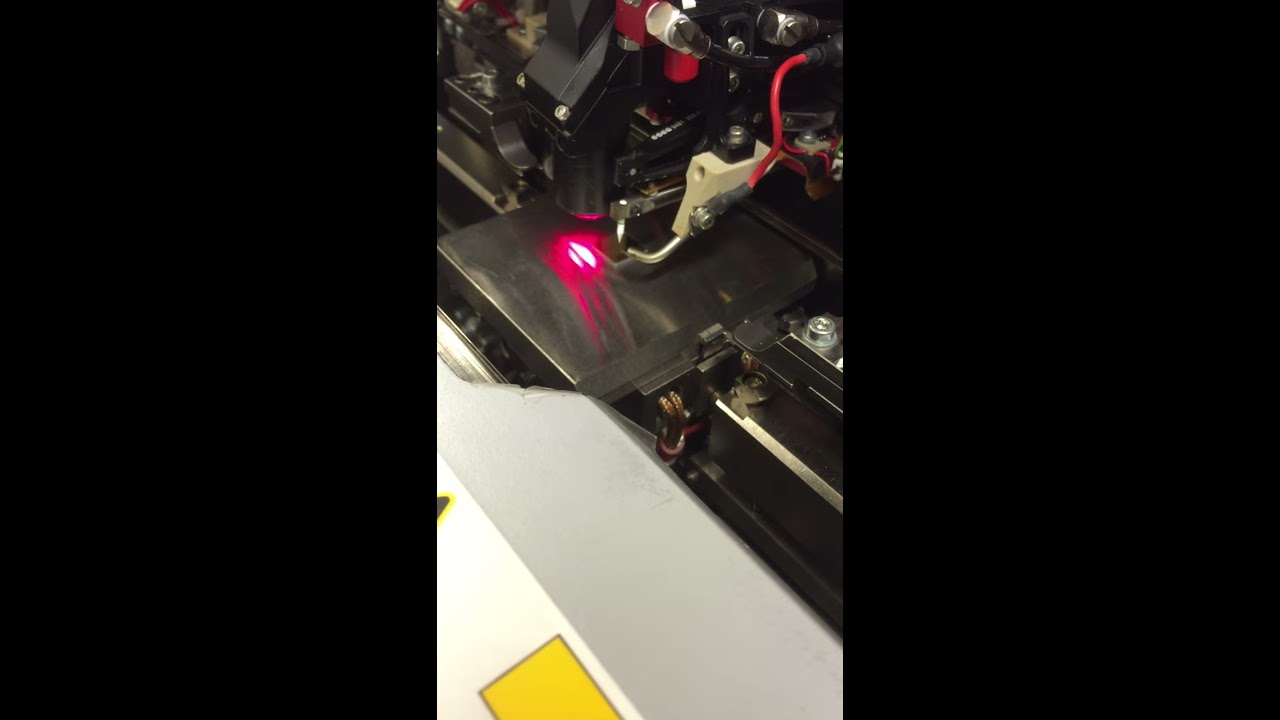

The evolution of twine bonding technology has ended in the growth of state-of-the-art machines able to executing frustrating methods effectually. Modern wire bonding machines combine automation facets that optimize construction cycles even though asserting excessive precision.

Benefits of Automated Wire Bonding Machines

Automated machines toughen the two velocity and consistency in creation environments. With features like programmable settings and genuine-time monitoring methods, brands can obtain larger yields with decreased errors quotes.

Wire Bonding Techniques Explained

Ball Bonding vs Wedge Bonding

Two basic recommendations dominate the wire bonding landscape:

- Ball Bonding: Utilizes a small ball fashioned on the finish of a gold or aluminum twine to create a bond. Wedge Bonding: Employs a wedge-fashioned instrument to make connections; superb for thicker wires or in which space constraints exist.

Both processes have their merits relying on application specifics.

Thermosonic vs Ultrasonic Bonding

These tactics involve one-of-a-kind vigour resources:

- Thermosonic Bonding combines warm with ultrasonic electricity for effective bonds. Ultrasonic Bonding relies totally on ultrasonic vibrations; it's quicker yet might not furnish as strong a connection as thermosonic programs.

Wire Bonding Applications Across Industries

Wire Bonding in Semiconductors

In semiconductor production, wire bonding establishes elementary connections between chips and substrates. Its reliability quickly impacts system functionality.

Applications in Automotive Electronics

As cars become greater reliant on electronics for operation and defense facets, amazing wire bonding ideas are obligatory to be sure reliability less than harsh conditions.

Medical Devices and Wire Bonding Solutions

Insulated twine bonding reveals its means into medical devices where reliability can imply existence or demise. Whether securing sensors or connecting ingredients inside implants, it’s very important that those bonds resist rigorous checking out.

Wire Bond Quality Control Measures

Ensuring tremendous bonds calls for strict pleasant keep watch over measures right through the creation job.

Common Testing Methods for Wire Bonds

Pull Test Shear Test X-ray Inspection Visual InspectionThese checks support recognize capacity matters early in creation cycles ahead of they strengthen into pricey mess ups.

Wire Bond Reliability Factors

Environmental Considerations in Wire Bond Reliability

Environmental factors equivalent to temperature fluctuations and moisture degrees severely have effects on bond integrity through the years.

- Implement ESD coverage procedures. Use conformal coatings for enhanced longevity in opposition to environmental stressors.

Long-term Reliability Testing Procedures

Conduct popular lengthy-time period reliability assessments to determine that bonds can face up to operational calls for over elevated periods.

Challenges Faced in Insulated Wire Bonding

Despite its advantages, insulated twine bonding comes with demanding situations:

Selecting useful insulation constituents will also be difficult. Machine calibration needs to be certain to forestall defects throughout the time of production. Environmental regulations may additionally hinder assured materials utilized in insulating layers.Wire Bond Failure Analysis Techniques

Understanding why bonds fail is needed for making improvements to methods:

Analyze root causes as a result of failure analysis protocols. Implement corrective actions situated on findings from failure mode prognosis reports. Regularly assessment overall performance data to determine developments optimal to disasters.Costs Associated with Wire Bond Processes

Understanding quotes associated with cord bonding facilitates companies allocate budgets more with no trouble:

| Type | Cost Estimate | |-----------------------------|---------------| | Manual Wire Bonder | $5K - $20K | | Semi-Automatic Bonder | $20K - $75K | | Fully Automatic Bonder | $100K+ |

Investments vary extensively based on equipment knowledge and automation stages.

Training Programs for Effective Wire Bonding

To hinder velocity with market advancements:

- Implement ongoing schooling techniques overlaying matters from common principles to superior procedures. Encourage participation in online courses or webinars targeted on state-of-the-art trends in insulated wire bonding know-how.

Learning Resources for Engineers

For engineers looking to grasp insulated wire bonding:

- Access tutorial supplies which include "cord bonding tutorial" video clips on line. Download "twine bonding PDF" archives from professional sources detailing approaches and methodologies.

Case Studies Illustrating Successful Applications

Examining effectual case stories highlights how insulated twine bonding enhances functionality throughout loads of sectors:

Power module purposes integrating ribbon bonded generation leading to enhanced performance costs via 30%. Medical devices making use of aluminum bonded wires showcasing long-term toughness even under tension checking out prerequisites.Frequently Asked Questions (FAQs)

1. What are the most different types of insulated wires used in electronics?

Insulated wires by and large encompass aluminum wires covered with layers like polyimide or silicone rubber that support sturdiness and efficiency lower than plenty of prerequisites.

2. How does temperature have an impact on the effectiveness of insulated wire bonds?

Temperature ameliorations can result in growth or contraction that might weaken bond integrity; for that reason making sure excellent thermal administration throughout operation is principal.

three. What testing ways guarantee pleasant regulate in bonded wires?

Quality management employs a great number of trying out programs inclusive of pull tests, shear exams in conjunction with visual inspection strategies making certain each bond meets required requirements earlier deployment into ultimate items.

4. Can you give an explanation for how environmental components impression bonded wires?

Moisture exposure could lead corrosion while critical temperatures would possibly result in fatigue; to that end utilizing protective coatings will become priceless whilst designing assemblies subjected harsher environments!

5 What industries receive advantages so much from evolved insulating techniques?

Industries such as automotive electronics healthcare strategies aerospace all leverage more suitable insulation houses making sure official functioning over longer lifespans!

6 Are there distinct practising packages obtainable focusing fully upon learning these suggestions?

Yes! Go to the website There are specialized programs constructed concentrated on folks aiming acquire accomplished skillsets surrounding latest methods applied within this area!

Conclusion

In conclusion, insulated cord bonding represents an simple development within digital production methods this day! As we explored at some stage in this accomplished consultant—it now not solely improves standard overall performance yet also notably complements sturdiness across assorted programs ranging car sectors medical instruments capability modules alike! By leveraging rising technology coupled alongside prevalent practices engineers will keep pushing barriers creating modern suggestions raising requirements nice reliability!