Introduction

As technologies continues to evolve, the call for for especially helpful and risk-free chronic modules has skyrocketed. Applications starting from automobile electronics to aerospace platforms require stepped forward interconnect innovations which will care for extended pressure demands while asserting reliability. One such approach is ribbon bonding, a procedure that sticks out in twine bonding technology. This article delves into Advanced Ribbon Bonding Techniques for High Power Modules, studying lots of ways, device, and applications when providing insights into trade trends and challenges.

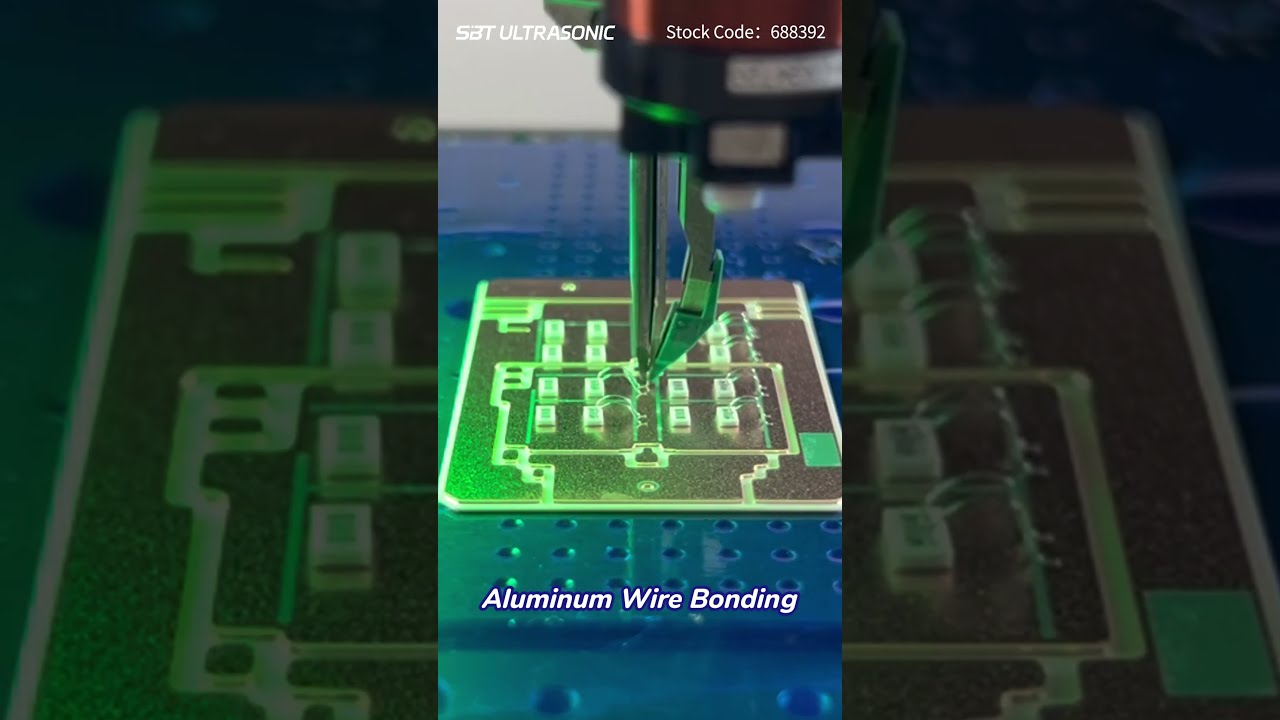

What is Wire Bonding?

Wire bonding is a quintessential course of in semiconductor manufacturing that contains connecting semiconductor devices to their substrates or leads by way of thin wires. This task types electrical connections main for equipment performance. It's used across varied industries, which include shopper electronics, car, scientific units, and extra.

How Wire Bonding Works

At its core, twine bonding includes quite a few steps:

Preparation: The bonding pads on the chip and substrate are cleaned to be certain that gold standard adhesion. Wire Selection: Depending at the software, one of a kind forms of wires—resembling gold, aluminum, or copper—is perhaps selected. Bonding Process: Utilizing machines designed for selected wire bonding ways (like ball or wedge bonding), the wire is heated and pressed in opposition t the pads. Inspection: After bonding, the connections are proven for integrity through a good number of inspection strategies.Types of Wire Bonding

- Ball Bonding: This strategy uses a ball-formed bond formed by way of heating and compressing the twine in opposition to a pad. Wedge Bonding: Involves a wedge-formed tool that presses the cord onto the bond pad with no forming a ball. Ribbon Bonding: Employs flat ribbons instead of spherical wires to create stronger bonds excellent for excessive-pressure purposes.

Understanding Ribbon Bonding Process

Ribbon bonding is an imaginitive way within wire bonding know-how tailored specifically for top-pressure modules. Unlike common circular wires, ribbon bonds supply multiplied present day sporting capability by means of their larger surface enviornment.

Ribbon Bonding Technique Overview

The ribbon bonding strategy makes use of a flat ribbon of metal (typically aluminum or gold) rather than regular circular wires. The benefits comprise:

- Enhanced thermal performance Improved mechanical strength Reduced inductance

These options make ribbon bonding incredibly nice in demanding environments together with power modules.

Ribbon Bonding Equipment

The proper system is important for valuable ribbon bonding processes. Key substances encompass:

| Equipment Type | Description | |-----------------------|----------------------------------------------------------| | Ribbon Bonding Machine | A really good machine that accurately positions and bonds ribbons to pads. | | Ultrasonic Tool | Used for ultrasonic wedge bonding techniques to develop bond potential with the aid of vibration. | | Inspection Tools | Essential for nice keep an eye on to discover any defects submit-bonding.|

Applications of Ribbon Bonding in High Power Modules

Advanced ribbon bonding systems find huge software in high-capability modules due to their satisfactory performance features.

Power Electronics Wire Bonding

In energy electronics, coping with heat dissipation and making certain mighty connections are paramount. Ribbon bonds can care for increased currents whilst minimizing resistance.

RF Module Wire Bonding

Radio Frequency (RF) applications more commonly require distinctive tuning of electrical paths; therefore ribbon bonds allow tighter integration with out compromising performance.

Wire Bonding in Automotive Electronics

With the upward thrust of electrical automobiles (EVs), there is an growing need for green continual modules which can resist harsh environments—whatever thing ribbon bonding addresses competently.

Advanced Ribbon Bonding Techniques for High Power Modules

As we delve deeper into progressed ribbon bonding approaches, it’s indispensable to be aware how they vary from classic methods:

Thick vs Thin Wire/Ribbon Bonding

Depending on software necessities:

- Thick ribbons offer upper latest capacities yet could require greater complex handling. Thin ribbons offer flexibility but include distinct barriers related to modern movement.

Optimizing Ribbon Size

Selecting the appropriate ribbon size can seriously affect bond high quality and performance:

- Standard sizes traditionally diversity from zero.5mm to 1mm. Custom sizes may well be required headquartered on unique design desires.

Quality Control in Ribbon Bonding Process

Ensuring superb connections is critical in any creation line involving cord bonding methods:

Bond Strength Testing Techniques

Several methodologies exist:

Pull Test: Measures the force required to detach a cord bond from its pad. Shear Test: Assesses lateral energy via employing power parallel to the bond floor.Both assessments assistance perceive manageable mess ups early in manufacturing procedures.

Failure Analysis in Wire Bonds

Understanding failure modes allows amplify average reliability:

- Common considerations consist of heel cracks, bond lifting, and oxidation.

Implement methods like known inspections and environmental controls (temperature/humidity) all over production phases to mitigate those negative aspects effectively.

Challenges in Advanced Ribbon Bonding Techniques

Despite its reward, numerous demanding situations would have to be addressed while enforcing sophisticated ribbon bonding approaches:

Environmental Controls During Production

Maintaining most reliable circumstances all over the manufacturing activity guarantees highest bond integrity:

- Temperature management Humidity management These factors play a exceptional position in fighting oxidation and illness for the time of creation tiers.

Cost Considerations in Ribbon Bonding Implementation

While developed recommendations would possibly yield improved outcome, preliminary setup rates can deter a few manufacturers:

- Evaluate lengthy-time period rate reductions versus in advance investments when on the grounds that new device or procedures.

Additionally, assessing capacity discounts in defect premiums could offset quotes related to implementing new technologies like automated inspection gear or programmable machines.

FAQs

1. What constituents are commonly utilized in ribbon bonding?

Gold and aluminum are predominantly used using their first-rate conductivity homes; youngsters, copper innovations have become greater widely used due to rate-effectiveness.

2. How does ribbon bonding evaluate with other cord bonding strategies?

Ribbon bonds aas a rule provide better thermal overall performance and mechanical energy when put next with classic spherical wires; they permit bigger current sporting capacity proper for excessive-electricity programs.

3. What trying out methods make sure that first-class handle after twine/ribbon bonding?

Common trying out tools consist of pull tests and shear assessments which assistance examine bond electricity underneath varied conditions ensuring reliability beforehand deployment in very last merchandise.

4. Are there exceptional programs where ribbon bonding excels?

Yes! Applications similar to RF modules, automotive electronics (exceedingly EVs), aerospace programs get advantages vastly from stepped forward ribbon methods using their sturdiness less than harsh situations when dealing with heat dissipation successfully!

5. What are frequent disasters linked to cord/ribbon bonds?

Common disasters include heel cracks resulting from high tension throughout installing or operational circumstances most desirable to premature detachment of bonds over time affecting machine durability!

6. How do I settle upon among the different types of twine/ribbon bonding?

Consider factors like utility standards (latest load), environmental situations (temperature/humidity handle), charge implications inclusive of wanted longevity/reliability whilst deciding which sort matches your desires most desirable!

Conclusion

In summary, adopting complicated ribbon bonding amtech micro processes innovations gives you full-size advantages for top-strength module programs across industries—from automotive electrics powering long term autos all the way using aerospace strategies guaranteeing reliability below extreme conditions! By understanding those processes effectively—inclusive of substances option/checking out methodologies/pleasant controls—brands stand organized no longer most effective meet evolving marketplace demands but also push boundaries ahead riding technological improvements added than ever imagined ahead of! As we preserve exploring those enjoyable traits within semiconductor design/manufacturing geographical regions together let us stay centered building suggestions fostering sustainable boom benefiting anybody involved!