Introduction

In the quick-paced international of electronics production, the importance of powerful interconnection ideas won't be able to be overstated. Among those, twine bonding emerges Learn more as a cornerstone technologies. This article pursuits to deliver a entire diagnosis of cord bonding machines and equipment, delving into lots of factors corresponding to methods, technologies, procedures, purposes, and future traits within the market. Understanding wire bonding is principal for engineers and producers alike in reaching reliability and great in electronic units.

What is Wire Bonding?

Wire bonding is a method used to create electrical connections among semiconductor chips and their packages or substrates. It comprises through great wires—traditionally manufactured from gold, aluminum, copper, or silver—to establish those connections. The system can also be performed simply by diverse strategies akin to ball bonding, wedge bonding, and ribbon bonding.

The Wire Bonding Process

The wire bonding job usually carries several key steps:

Preparation: The surface of the bond pads must be cleaned to ascertain good adhesion. Wire Feeding: The bonding desktop feeds the wire simply by a capillary device. Bonding: The machine applies warmness and ultrasonic strength (or rigidity) to create a bond. Loop Formation: The cord is shaped into loops for additional power. Trimming: Excess wire is trimmed to finalize the bond.This difficult course of guarantees trustworthy connections which are significant for the functionality of electronic instruments.

Types of Wire Bonding Techniques

Wire bonding era has advanced through the years, resulting in a number of tactics suited for one of a kind applications:

Ball Bonding

Ball bonding is among the many such a lot regular programs, mainly as a result of gold or copper wires. In this system:

- A ball is shaped on the give up of the cord through heat. The ball is then pressed onto the bond pad to style a connection.

Wedge Bonding

Wedge bonding employs a flat instrument other than a ball to make touch with both surfaces. This manner is enormously useful for:

- Aluminum wires Applications requiring lower temperatures

Ribbon Bonding

Ribbon bonding makes use of flat ribbons rather then circular wires, taking into account increased modern-day capacities and lowered inductance. It's in the main used in persistent modules and high-frequency applications.

Wire Bonding Machines: An Overview

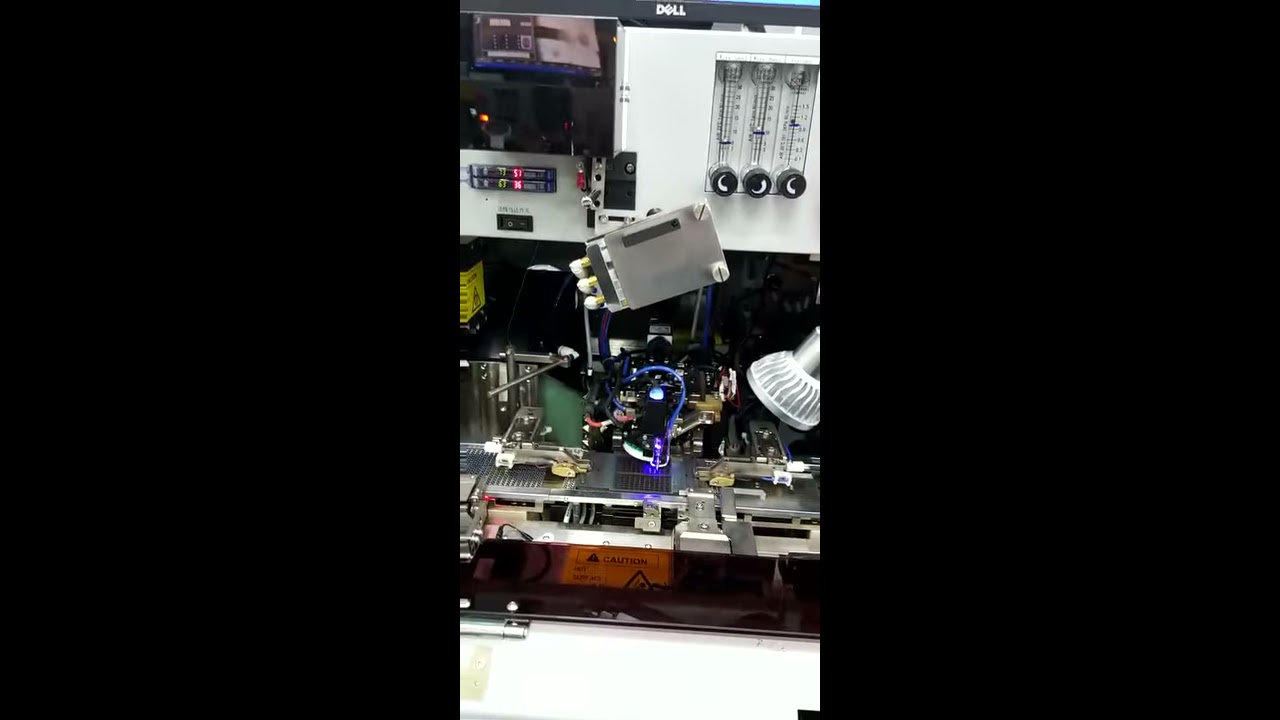

What Are Wire Bonding Machines?

Wire bonding machines are really good machine designed to automate the cord bonding strategy. They are available loads of paperwork adding guide, semi-automatic, and absolutely automatic machines.

Features of Modern Wire Bonding Equipment

Modern wire bonding approaches offer different capabilities geared toward expanding performance and making certain first-rate bonds:

- Programmable settings Advanced monitoring systems Automated inspection tools

These beneficial properties guide streamline creation whilst asserting stringent best manage standards.

How Wire Bonding Works: A Technical Insight

Understanding how cord bonding works comprises greedy equally mechanical and thermal points:

Mechanical Pressure: The computing device exerts rigidity in the course of the bond formation which allows for textile deformation. Thermal Energy: Heat is helping facilitate atomic diffusion at the interface between constituents growing stable bonds.Bond Strength in Wire Bonding

Bond potential is important for reliability in digital units; it can be stimulated by using reasons inclusive of:

- Material desire (gold vs aluminum) Environmental conditions Process parameters (temperature and power)

Measuring bond potential basically comprises pull assessments or shear tests designed to guage the integrity of connections.

Wire Bonding Applications Across Industries

Wire bonding unearths its application throughout distinctive sectors with the aid of its adaptability:

1. Wire Bonding in Semiconductors

The semiconductor marketplace is dependent seriously on twine bonding for connecting integrated circuits (ICs) to packages or substrates accurately.

2. Wire Bonding for Medical Devices

Medical units require prime-reliability connections; hence many make the most of advanced twine bonding strategies like quality pitch ball bonding.

three. Automotive Electronics Wire Bonding

As cars transform extra complicated with electronics, dependableremember interconnections by cord bonds are imperative for safe practices programs and infotainment capabilities.

The Economics of Wire Bonding: Cost Considerations

Understanding the rate implications linked to the several cord bonding approaches can lend a hand manufacturers optimize their operations:

1. Initial Investment vs Long-time period Costs

While automatic machines have a bigger upfront check, they regularly cause curb hard work costs over time as a consequence of elevated throughput.

2. Material Costs: Gold vs Aluminum vs Copper Wires

Gold wires are extra expensive than aluminum but provide more advantageous efficiency beneath certain stipulations (e.g., top-frequency packages).

Quality Control in Wire Bonding Processes

Ensuring caliber for the duration of manufacturing methods can prevent defects that result in failure modes later on:

1. Visual Inspection Techniques

Visual inspection is still probably the most maximum straightforward methods for selecting manageable things early on together with bond raise-off or heel cracks.

2. Non-unfavourable Testing Methods

Techniques consisting of x-ray inspection or automated optical inspection (AOI) allow manufacturers to evaluate bond integrity with out damaging formulation.

Wire Bond Failure Analysis: Understanding Defects

Fail-dependable design calls for realizing how screw ups manifest inside of bonded structures:

Common Types of Wire Bond Failures

| Failure Mode | Description | |---------------------|-----------------------------------------------| | Heel Cracks | Cracks at the base of the bond | | Lift-Off | Complete detachment from bond pad | | Oxidation | Deterioration by means of environmental exposure |

Understanding these failure modes supports tell more beneficial layout practices and preservation schedules.

FAQs

1. What components are repeatedly used for cord bonds?

Gold, aluminum, copper, and silver are known supplies used for wire bonds via their conductive properties.

2. How does temperature have effects on the cord bonding approach?

Temperature performs a very good function; increased temperatures can beef up bond electricity yet may even lead to materials degradation if not managed excellent.

3. What industries predominantly use cord bonding era?

Industries come with semiconductors, automotive electronics, clinical devices, aerospace engineering, telecommunications, etc.

four. How can I study greater approximately twine bonding tactics?

Numerous instruments exist online consisting of tutorials reachable in PDF layout or educational video clips that furnish visible demonstrations of tactics worried in wire binding.

five. What are some common demanding situations confronted all over wiring processes?

Challenges incorporate handling thermal expansion variations between materials used or stopping oxidation prior to making connections which could compromise integrity.

Conclusion

In conclusion, working out "A Deep Dive into Wire Bonding Machines and Equipment" unearths its significant function across many different industries—from semiconductors to automobile electronics—in which solid interconnections variety the backbone of present day era development efforts at the moment! By mastering either ordinary concepts like ball/wedge/ribbon ways which include new concepts rising from developments inside Industry four.zero frameworks—brands stand poised now not simply with ease live on but thrive amidst ever-increasing competition panorama in advance!

With talents gained throughout this exploration—whether you might be an engineer in the hunt for functional insights into enforcing positive thoughts within your personal operations—or without difficulty curious approximately state-of-the-art advancements shaping long term landscapes—rely that thorough comprehension leads at last closer to better productiveness & success inside of any box related to challenging electronic platforms!